How to Source Replacement Molded Case Circuit Breakers (MCCBs)

Wednesday, November 6, 2024

When managing older industrial electrical systems, finding replacement molded case circuit breakers (MCCBs) is crucial. As key components in power distribution, MCCBs protect systems from overloads and short circuits. However, sourcing compatible replacements can be difficult when dealing with discontinued or legacy models. Here’s a comprehensive guide to locating high-quality MCCBs, ensuring your systems remain operational, safe, and compliant.

Begin with Accurate Specifications

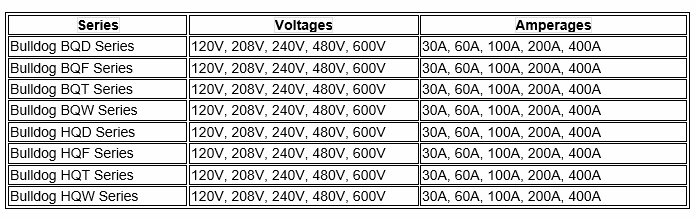

The first step in finding a compatible replacement is documenting the breaker’s detailed specifications. Molded case circuit breakers come in a range of configurations, so you’ll want to record the following:

- Model Number and Brand: These indicate the exact type and often help suppliers match specifications.

- Voltage and Amp Rating: Ensure compatibility with the system’s power requirements.

- Trip Characteristics: Different MCCBs have specific trip functions that need to align with the system.

- Physical Dimensions: Size compatibility is essential to fit the breaker’s enclosure and maintain system integrity.

These details are critical in minimizing downtime, as accurate documentation allows for quick identification and sourcing of the correct replacement breaker and helps our sales staff ensure we get the exact breaker you need.

* Note the example below with the red arrow the amperage, voltage and model number for that specific Square D breaker.

Explore Refurbished, Tested Options from a Trusted Supplier

While new MCCBs are ideal, they can be expensive, especially if the model is obsolete or specific to legacy systems. Used and tested MCCBs are an excellent alternative, often available at a fraction of the cost of new models while offering similar performance. Quality used units undergo a rigorous testing process to ensure they meet or exceed industry standards and may come with documented test results.

Why Choose Used and Tested MCCBs?

Refurbished MCCBs provide:

- Cost Savings: Ideal for budget-conscious operations without sacrificing quality.

- Extended Component Life: Refurbishment processes allow older equipment to perform reliably.

- Reliability and Warranty: Reputable suppliers back their refurbished MCCBs with warranties and stringent testing procedures, offering peace of mind.

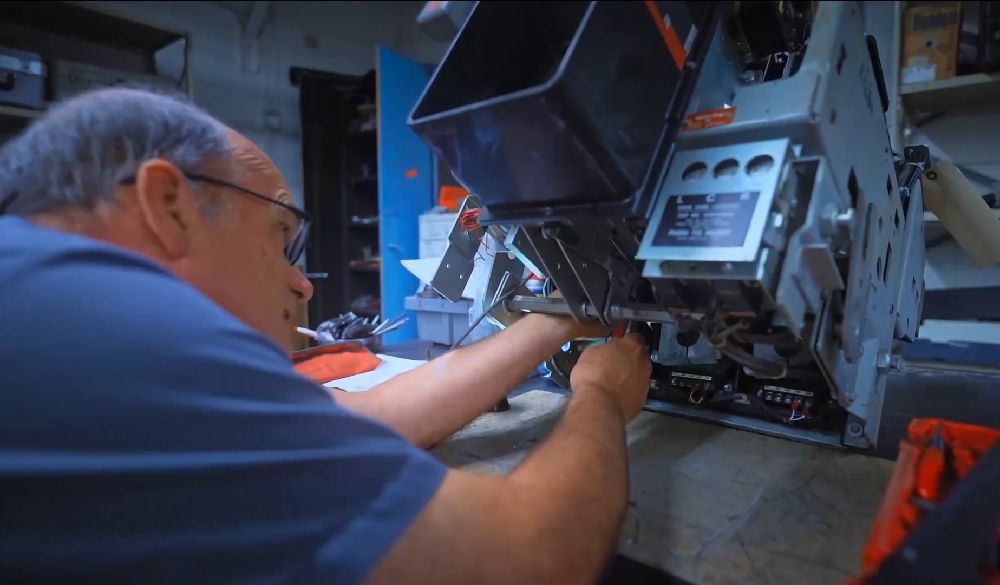

EMSCO specializes in providing high-quality refurbished MCCBs that meet these criteria. Our molded and insulated case breakers are thoroughly tested, restored, and come with warranties to ensure dependable performance.

Work with a Supplier Experienced in Hard-to-Find Parts

For those managing legacy systems, finding specific MCCBs that may be discontinued or obsolete can be difficult. Working with a supplier specializing in vintage and hard-to-find components simplifies this process. EMSCO’s extensive inventory includes many obsolete breakers, allowing us to meet the needs of facilities requiring unique or discontinued models.

An experienced supplier can provide:

- Personalized Sourcing: Identifying compatible replacements when exact models aren’t available.

- Technical Expertise: Offering guidance on selecting equivalent options or advising on alternatives.

At EMSCO, our team brings decades of industry experience to each customer interaction, ensuring that you get reliable support to make informed decisions.

Ensure Availability and Prioritize Quick Lead Times

Minimizing downtime is a top priority for contractors, facilities managers, and engineers alike. Quick access to replacement MCCBs is essential to avoid costly delays. Partnering with a supplier that maintains a large, well-organized inventory of MCCBs can reduce lead times significantly.

Why EMSCO’s Inventory Matters

EMSCO’s 250,000-square-foot Minneapolis warehouse houses one of the largest selections of MCCBs, with thousands of models tested in-stock and ready to ship. Our centralized location allows for efficient shipping across North America, ensuring fast access to essential parts. With EMSCO’s extensive stock, you’re better positioned to receive the breaker you need without prolonged wait times, keeping your projects on track and facilities operational.

Verify Quality and Warranties on Refurbished Parts

When it comes to MCCBs, quality is paramount. Replacement components must not only fit correctly but also meet safety standards to perform effectively. Partnering with suppliers who follow strict refurbishing and quality control processes is key to ensuring that each breaker functions as intended.

Quality Standards to Look For Suppliers who adhere to recognized standards like PEARL (Professional Electrical Apparatus Reconditioning League) demonstrate a commitment to quality. PEARL standards ensure that refurbished components have undergone comprehensive inspection and testing to meet specific industry requirements. Additionally, a warranty provides extra assurance, underscoring the supplier’s confidence in their refurbished products.

EMSCO’s quality assurance process is rigorous. Each breaker is tested for safety and durability, meeting or exceeding industry standards, and comes with a warranty to protect your investment. Our commitment to quality ensures that the equipment we provide is ready to perform reliably in critical settings.

Plan for the Long Term with Dependable Replacements

By selecting high-quality refurbished MCCBs, you can extend the life of your existing system without investing in a full upgrade. Reliable replacements are essential for managing equipment costs and maintaining operational efficiency. With the right MCCBs, you can keep your legacy systems functioning as intended, meeting safety standards and avoiding the high costs associated with complete system replacements.

Why EMSCO?

Sourcing replacement MCCBs doesn’t have to be complicated. EMSCO’s vast inventory, fast lead times, and experienced team provide a streamlined solution to meet your needs. Whether you’re a contractor needing quick parts for a project, a facilities manager seeking to minimize downtime, or an engineer looking for performance-tested breakers, EMSCO is ready to assist.

Explore our molded and insulated case breakers or contact us today to see how EMSCO can support your replacement circuit breaker requirements with quality, efficiency, and expertise.