Powering Recovery: How EMSCO Helped Restore Temporary Power at Skyline Tower

Monday, November 10, 2025

When the Skyline Tower fire in St. Paul, Minnesota displaced hundreds of residents and left the high-rise without power, getting the building back online quickly and safely became a top priority. For residents, restoration meant more than lights—it meant stability, security, and a path back to normalcy.

To make that happen, NAC Mechanical & Electrical Services partnered with EMSCO to source the temporary power equipment required to restore service to the building. With essential systems down and repairs expected to take time, NAC turned to EMSCO for a fast, reliable solution they could count on.

Understanding the Challenge

Large residential complexes like Skyline Tower rely on intricate electrical systems that distribute power across dozens of floors, elevators, and life-safety infrastructure. After a major fire, these systems can be severely compromised—making it unsafe to reconnect to the grid until inspections, testing, and repairs are completed.

That’s where temporary power comes in. A well-designed temporary system provides a safe, controlled way to energize key building operations—everything from emergency lighting and water pumps to heating, ventilation, and staging areas for cleanup crews.

But designing and deploying a temporary power setup for a 24-story building is no small task. It requires high-capacity distribution equipment, coordination between multiple teams, and the ability to deliver components fast—because every hour without power adds risk and disruption for residents and staff.

The Solution: Equipment That Restores Reliability

To support NAC’s recovery plan, EMSCO supplied a Square D 3000A MLO panel, along with (3) 800A feeds and (1) 1200A feed. This configuration formed the foundation of a temporary power restoration system that will safely support essential building operations while permanent repairs are underway.

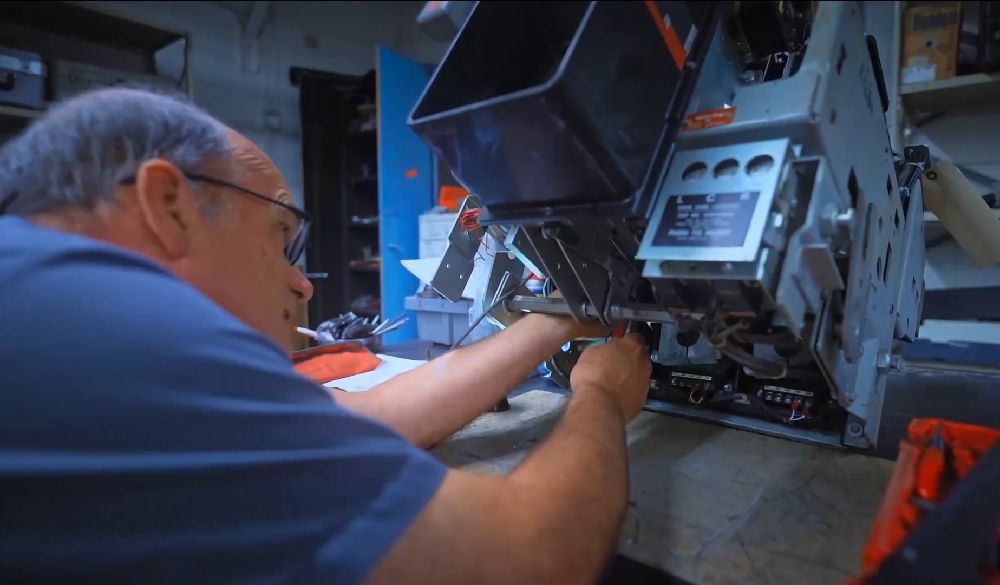

These components were carefully selected to match the site’s temporary load demands and compatibility requirements—ensuring seamless integration once installed. EMSCO’s team confirmed functionality and performance through its standard reconditioning process, verifying that each piece met OEM specifications and safety standards before shipment.

Because EMSCO maintains one of the largest in-stock inventories of reconditioned electrical equipment in the country, NAC didn’t need to wait weeks for a manufacturer lead time. The equipment was sourced, prepared, and shipped quickly—helping the contractor stay on schedule and ensuring the building could move one step closer to power restoration.

Partnering for Success

Collaboration is at the core of every successful recovery project. EMSCO worked closely with NAC Mechanical & Electrical Services, providing not just equipment, but support and expertise throughout the sourcing process.

By leveraging EMSCO’s extensive product knowledge and inventory depth, NAC was able to find exactly what was needed for a project of this scale—without compromise on quality or speed.

This partnership highlights the critical role suppliers play in disaster recovery: while contractors handle the installation and on-site coordination, EMSCO ensures the right equipment is available and ready to go when it’s needed most.

“Temporary power systems are only as strong as the components behind them,” said an EMSCO project specialist. “Our goal is to make sure contractors can focus on restoration—not on waiting for parts.”

The Importance of Temporary Power in Disaster Recovery

Temporary power isn’t just about keeping the lights on—it’s about enabling safety, productivity, and continuity during the most challenging circumstances.

In large-scale incidents like fires, floods, or equipment failures, downtime can threaten building integrity and delay recovery for weeks. Having a dependable temporary power solution bridges the gap between emergency response and full restoration.

Some of the most common reasons facilities need temporary power include:

Fire or water damage to switchgear or transformers

Major equipment failures causing extended outages

Planned maintenance or electrical upgrades requiring power isolation

Construction projects where permanent systems aren’t yet installed

By partnering with a supplier like EMSCO, contractors and facility teams can secure high-capacity, field-tested equipment fast—reducing downtime, minimizing risk, and keeping critical systems operational.

A Legacy of Reliability

At EMSCO, we take pride in supporting the contractors, facility managers, and electrical professionals who respond when disaster strikes. From temporary power setups to large-scale restorations, we help our partners get operations up and running fast.

Backed by over 75 years of industry expertise and one of the largest inventories of reconditioned electrical equipment in the country, EMSCO delivers when speed and reliability matter most. Our commitment is simple: provide dependable electrical solutions that help others win the day—safely, efficiently, and confidently.

Moving Forward

The Skyline Tower project stands as a reminder that preparation and partnership make all the difference in recovery. With the right equipment, dependable suppliers, and experienced professionals, even the most complex power restoration projects can be executed with confidence and precision.

As the building’s recovery continues, EMSCO remains proud to have played a part in helping NAC Mechanical & Electrical Services bring power—and peace of mind—back to a community in need.

Find. Fix. Fast.

That’s the EMSCO way.

Learn More

If your facility, property, or project requires temporary power systems or disaster recovery equipment, EMSCO can help.

Explore our inventory of reconditioned switchgear, transformers, and distribution equipment at emscomn.com

If you're unsure about the specific breaker model, just send us a photo, and we'll assist you in identifying it.

If you're unsure about the specific breaker model, just send us a photo, and we'll assist you in identifying it.