Industrial Power Distribution Explained

Thursday, April 11, 2024

Industrial power distribution serves as the lifeblood of manufacturing and production facilities, powering the equipment and machinery vital for operational success. In this comprehensive guide, we'll delve into the functions of industrial power distribution and explore its key components that ensure efficiency, reliability, and safety in industrial operations.

Functions of Industrial Power Distribution:

One of the primary functions of industrial power distribution is to efficiently and reliably power the equipment and machinery essential for manufacturing and production processes. Industrial facilities rely on a vast array of equipment, ranging from motors and pumps to conveyor systems and robotic arms, all of which require a steady and uninterrupted supply of electricity to operate effectively.

Industrial power distribution systems ensure that each piece of equipment receives the appropriate voltage and current required for optimal performance. This involves managing power quality to minimize fluctuations and disturbances that could affect equipment operation. By maintaining stable voltage levels and mitigating issues such as voltage sags, surges, and harmonics, power distribution systems safeguard equipment from damage and ensure consistent production output.

Furthermore, industrial power distribution systems play a crucial role in load management, balancing the electrical load across different circuits and phases within the facility. By distributing the load evenly, these systems prevent overloading and voltage imbalances that could lead to equipment failures or disruptions in production. Effective load management optimizes energy usage and maximizes the efficiency of electrical infrastructure, ultimately reducing operating costs and improving the overall performance of industrial operations.

In essence, industrial power distribution systems serve as the lifeline of manufacturing and production facilities, powering the equipment and machinery that drive productivity and profitability. By providing reliable and efficient electrical energy to support industrial processes, these systems enable businesses to meet production targets, maintain competitiveness, and adapt to changing market demands effectively.

Key Components of Industrial Power Distribution:

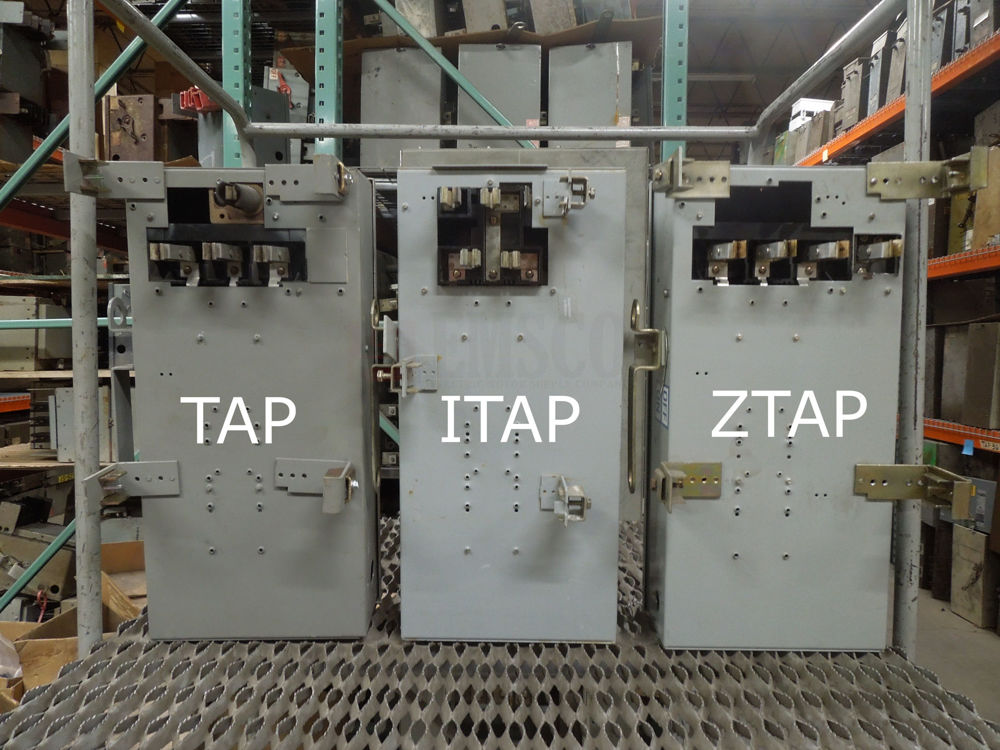

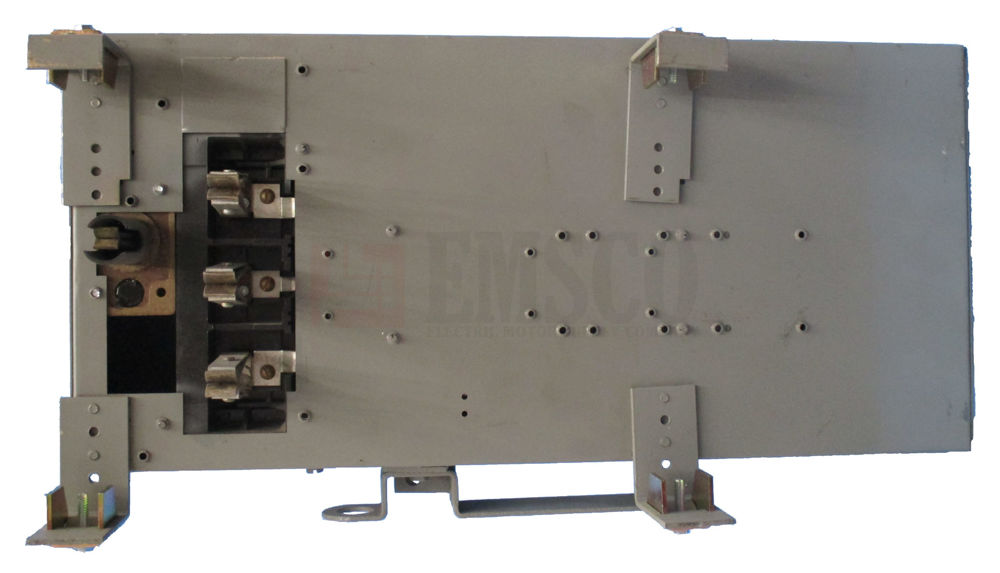

Bus Ducts and Busways:

Serving as the main arteries of industrial power distribution systems, bus ducts and busways transport electrical currents from the main power source to various areas within the facility. These robust metal enclosures house insulated conductors made of copper or aluminum and provide the essential infrastructure for delivering power precisely where it's needed.

Switchgear and Circuit Breakers:

Acting as the guardians of electrical integrity, switchgear and circuit breakers protect electrical circuits from overloads and faults. Switchgear encompasses switches, fuses, and other protective devices, while circuit breakers automatically interrupt the flow of electricity upon detecting abnormalities, ensuring equipment and personnel safety.

Transformers:

Transformers play a pivotal role in shaping voltage characteristics, stepping up or down voltage levels to match equipment requirements. They facilitate efficient transmission of electrical energy over extended distances while maintaining optimal power quality across the distribution network.

Conclusion:

Industrial power distribution systems are the backbone of modern manufacturing and production facilities, ensuring efficiency, reliability, and safety in industrial operations. By understanding the functions and key components of these systems, businesses can optimize their power distribution infrastructure to drive productivity, reduce costs, and maintain competitiveness in today's dynamic industrial landscape.

If you're looking to upgrade or replace any part of your industrial power distribution system, please give us a call today (1-800-328-1842) and let us discuss how we can help with your needs.